Flexible Stainless Steel Hoses are the premier engineering solution for conveying fluids and gases in extreme operating conditions. Combining a corrugated inner core with a flexible wire braid, these hoses offer unmatched resistance to high temperatures, low temperatures, high pressure, and chemical corrosion.

At Glory Engineering Supplies, we've built this page as a complete technical reference. Whether you are a specialized engineer seeking precise specifications or a technician needing a reliable solution, you'll find everything required to select the perfect hose for your application—across our **full size range from 1/4" up to 12"**.

We maintain a massive inventory of all hose diameters, from 1/4" instrument hoses to 12" large-bore industrial lines, ready for immediate dispatch.

We use only the highest-grade stainless steel (SS 304, SS 316, & SS 321) to ensure maximum corrosion and temperature resistance for a long, stable service life.

Our expert technicians are equipped to professionally TIG weld and assemble any end connection (Flanges, Cam Locks, NPT/BSP Threads) for a leak-proof seal.

Our team members are engineers, not just salespeople. We provide full technical support to help you calculate pressure, temperature, and select the exact hose.

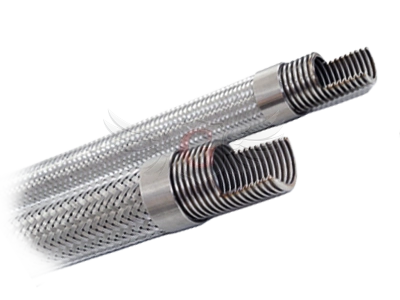

A stainless steel hose assembly consists of two main parts, with options for added layers:

The flexible, leak-proof inner tube. Its annular (ring-shaped) design provides excellent flexibility and resistance to fatigue from vibration and flexing.

A layer of woven stainless steel wire (usually SS 304) that covers the core. Its primary function is to resist internal pressure and prevent the hose from elongating.

For high-pressure applications, a second braid layer is added. This significantly increases the hose's working pressure and burst pressure (Burst Pressure).

For highly corrosive chemicals, the inner core can be lined with materials like PTFE (Teflon) to provide universal chemical resistance while maintaining flexibility.

Choosing the right alloy for the inner core is critical for performance. The braid is typically SS 304 (as it doesn't touch the media), but the core material must match your application.

| Alloy Grade | Key Difference | Nature of Use & Why You Should Choose It |

|---|---|---|

| SS 304 (The Workhorse) | Standard 18/8 Chrome-Nickel Alloy |

This is the go-to, cost-effective choice for general-purpose applications.

|

| SS 316 (The Protector) | Includes Molybdenum |

This is the "protector" against corrosion. The molybdenum adds superior resistance to chlorides.

|

| SS 321 (The Specialist) | Stabilized with Titanium |

This is the high-temperature specialist. The titanium prevents "carbide precipitation" (weld decay) at high temps.

|

Glory Engineering Supplies confirms our full stocking capability for all stainless steel hose diameters. Our inventory covers:

No matter your application's scale, we provide the right-sized hose with the same high quality and reliability.

The braid is what gives the hose its pressure rating. An unbraided hose has a very low pressure rating, suitable only for gravity flow or vacuum.

Note: All pressures listed are Maximum Working Pressures (MWP) at 70°F / 20°C. Pressure ratings **decrease** as operating temperature **increases**. Always consult our technical team for temperature correction factors.

| Hose Size (Inch) | Unbraided Hose | Single Braid | Double Braid |

|---|---|---|---|

| PSI / Bar | PSI / Bar | PSI / Bar | |

| 1/4" | 145 PSI | 2420 PSI | 3190 PSI |

| 3/8" | 72 PSI | 1639 PSI | 1967 PSI |

| 1/2" | 72 PSI | 1225 PSI | 1470 PSI |

| 3/4" | 43 PSI | 1034 PSI | 1241 PSI |

| 1" | 43 PSI | 796 PSI | 955 PSI |

| 1 1/4" | 43 PSI | 600 PSI | 720 PSI |

| 1 1/2" | 28 PSI | 557 PSI | 668 PSI |

| 2" | 28 PSI | 570 PSI | 684 PSI |

| 2 1/2" | 12 PSI | 500 PSI | 700 PSI |

| 3" | 10 PSI | 400 PSI | 600 PSI |

| 4" | 8 PSI | 300 PSI | 444 PSI |

| 5" | 6 PSI | 191 PSI | 306 PSI |

| 6" | 5 PSI | 165 PSI | 264 PSI |

| 8" | 6 PSI | 234 PSI | 374 PSI |

| 10" | 5 PSI | 230 PSI | 369 PSI |

| 12" | 3 PSI | 161 PSI | 257 PSI |

Use the S.T.A.M.P. acronym to select the correct hose:

Proper installation is the #1 factor in extending hose life. Most failures are caused by improper routing that creates excess stress, leading to braid fracture or core fatigue.

Problem: Twisting the hose during installation (like tightening a screw) puts constant torsional stress on the braid wires, causing them to fatigue and snap quickly.

This is the fastest way to destroy a hose.

Solution: Always ensure the hose bends in only one plane (like closing a book). Use two wrenches—one to hold the fitting steady, and one to tighten the connection.

Problem: Bending the hose tighter than its "Minimum Bend Radius" (especially near the fitting) over-stresses the braid and can cause the corrugations to "kink" or collapse, leading to failure.

Solution: Always provide a smooth, gentle curve. Use 90-degree elbows or a longer hose to make the turn without stressing the hose itself. Leave a straight section of hose after the fitting before starting a bend.

Problem: A hose that is stretched tight has no room to absorb pressure changes or movement. It pulls directly on the fittings, leading to braid failure and potential pull-out.

Solution: Always install the hose with a small amount of "slack" (extra length) to allow for pressure surges, thermal expansion, and machine vibration. This allows the hose to flex naturally.

Problem: Allowing the outer braid to rub against sharp edges, equipment, or even another hose will quickly wear through the wires, compromise the pressure rating, and lead to a burst.

Solution: Clamp the hose securely, or use a protective cover (like Firesleeve, a PVC sleeve, or a spring guard) if rubbing is unavoidable. Ensure a clear path for the hose's movement.

This is the most critical choice for the hose core:

The core difference is pressure rating. An unbraided hose has almost no pressure resistance. A Single Braid provides good pressure resistance for most standard applications. A Double Braid is used for High-Pressure (HP) applications, significantly increasing the working pressure, as shown in the table above.

This depends entirely on the size, braid, and material.

Yes, absolutely. Stainless steel hose (especially SS 321 core) is the first and safest choice for flexible steam lines due to its unique ability to handle the high temperature and pressure of steam safely.

Yes. Glory Engineering Supplies is one of the few suppliers that maintains a consistent stock of large-bore hoses, including 10" and 12", with the capability to custom-weld the required flanges for them immediately.

Whether you need a 1/4" instrument hose or a 12" main line, the Glory team is ready to serve you. Contact us today for a technical consultation or to request a quote.

Request a Quote Now