Quick Couplings, also known as Quick Disconnects, are fittings designed to provide a fast, simple, and secure "push-to-connect" link for pneumatic (air), hydraulic, or fluid lines. They allow for the rapid changing of tools or hose lines without the need for wrenches, shutting off valves, or bleeding the system.

At Glory Engineering Supplies, we've built this guide to serve as a complete technical reference. Whether you are an engineer designing a pneumatic system or a technician needing to match a tool, this page will help you understand the critical **interchange standards**, materials, and applications to select the perfect coupling.

We stock all major pneumatic interchange profiles, including Industrial (I/M), ARO, and Automotive (A/T), ensuring you can match your existing tools and lines.

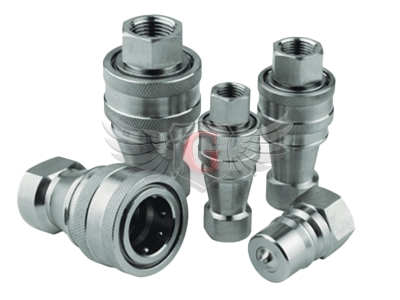

Our fittings are available in durable Plated Steel, corrosion-resistant Brass, and 316 Stainless Steel for food-grade or chemical applications.

Our team isn't just sales—we are engineers. We provide expert consultation to help you select the precise profile and size for your specific airflow (SCFM) needs.

Our couplers use high-quality seals and locking mechanisms to provide a secure, leak-free connection for high-pressure air and hydraulic lines.

The most important factor for a quick coupling is its **interchange standard** or "profile." A plug from one standard **will not** connect to a coupler from another, even if they are the same size. A Coupler (female) accepts a Plug (male).

Also known as Milton (M-Style). This is the most common standard in North America and globally for compressed air tools.

Very common in industrial plants and automotive facilities. Known for its high-flow design, delivering more power to tools.

Also known as Tru-Flate (T-Style). Widely used in car repair shops and service stations. Has a longer, narrower plug nose.

Heavy-duty, high-pressure couplings for hydraulic fluid. ISO 7241-A (Poppet) and 7241-B (Ball) are common standards.

We provide a full range of materials and connection types to fit any tool or hose.

| Material | Common Use | Available End Connections |

|---|---|---|

| Plated Steel | General purpose, high-durability. The standard for industrial air tools and hydraulics. | Male NPT, Female NPT, Hose Barb |

| Brass | Excellent corrosion resistance. Used for water, in-plant air, or in marine environments. | Male NPT, Female NPT, Hose Barb |

| Stainless Steel (316) | Maximum corrosion resistance. Used for food-grade (FDA), pharmaceutical, or chemical applications. | Male NPT, Female NPT, Hose Barb |

While we stock a full range, the "body size" of a pneumatic coupling determines its airflow (SCFM). The most common are:

Choosing the correct coupling is simple:

Connection is fast and tool-free:

The **Coupler** is the female half of the connection. It has the moving sleeve and internal locking balls. The **Plug** (also called a Nipple) is the male half that is inserted into the coupler.

No. Plugs and couplers from different interchange standards (e.g., Industrial, ARO, Automotive) have different shapes and dimensions. They are **not compatible** and will not connect, even if they are the same thread size (e.g., 1/4" NPT).

ABSOLUTELY NOT. THIS IS EXTREMELY DANGEROUS.

Using an air coupling for hydraulics will cause it to fail violently, which can cause severe injury. Hydraulic couplings are built from heavy-duty steel and use a different valving system. Never mix them.

A Universal Coupler is a special coupler designed to accept *both* **Industrial (I/M)** and **ARO** style plugs. This is very convenient for shops that may have a mix of tools. A "V-Style" or "High-Flow" plug is a modified Industrial plug that allows for greater airflow, increasing tool performance.

From a single fitting for your air tool to a complete system for your factory, Glory has the right interchange, material, and size. Contact our technical team for a consultation or request a quote today.

Request a Quote Now